One other large leap for mankind! NASA’s strongest rocket on the earth, Artemis 1, was launched on November 16. After a number of postponements as a consequence of technical issues and unfavorable climate situations, the liftoff passed off from Florida within the path of our pure satellite tv for pc. This mission marks the start of the American program, Artemis, which goals to return to the Moon. Its objective: to confirm that NASA’s spacecraft, Orion, is able to safely transporting a crew there.

With a view to elevate this house capsule, Aerojet Rocketdyne, an American firm specialised in rocket engine design, constructed 4 RS-25 engines that have been put in on the rocket. They have been designed to face up to probably the most excessive temperatures, but in addition to present the rocket sufficient energy to go across the Moon after which return to Earth. The particularity of those engines is that they’ve many 3D printed elements.

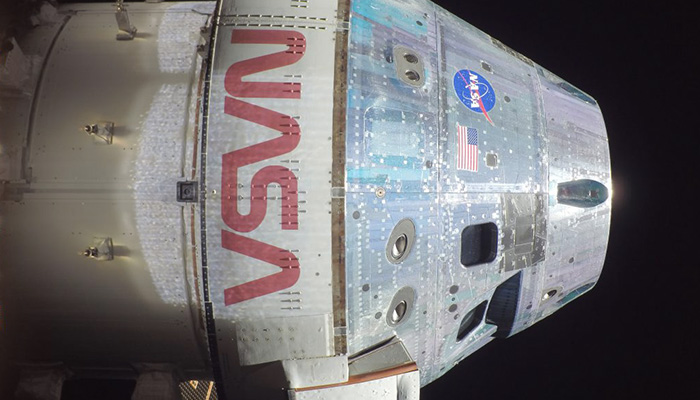

Picture of Orion, NASA’s spacecraft. (Picture credit: NASA)

3D Metallic Printing for the Manufacture of 3D Printed Components

For the design of the rocket, Aerojet Rocketdyne offered 39 propulsion parts, together with 38 liquid engines and 1 strong engine. The American firm additionally ready 14 high-pressure tanks. For almost all of its elements, it used 3D steel printing, particularly laser powder mattress fusion (LPBF). This know-how has decreased the general manufacturing prices of the engines by 35 %, in line with the producer. After years of delays and billions in overruns, additive manufacturing is proving its price when it comes to expense administration.

In the meantime, Northrop Grumman, one other U.S. aerospace and protection firm, has manufactured boosters designed for rocket thrust in the course of the first two minutes of liftoff of the NASA Artemis. Just like the RS-25 engines, these benefited from additive manufacturing know-how. Nevertheless, no info was given on the method used to construct these boosters.

“This profitable launch implies that NASA and our companions are heading in the right direction to discover farther than ever earlier than in house for the advantage of humanity,” mentioned Jim Free, NASA’s deputy affiliate administrator for Exploration Programs Improvement Mission Directorate.

With the Artemis missions, NASA paves the best way to a doable human presence on the Moon. If step one proves to be successful, the following mission, Artemis II, will happen on the earliest in 2024, and can carry 4 astronauts. Artemis III will then observe with the target of touchdown on the Moon. For extra info on the undertaking, click on HERE. In different makes use of of 3D printing in house, analysis can also be underway to attempt to discover a approach to construct on the Moon. The College of Central Florida has succeeded in 3D printing bricks from lunar regolith (the skinny mud discovered on the moon).

What do you consider the Artemis undertaking from NASA? Tell us in a remark beneath or on our LinkedIn, Fb, and Twitter pages! Don’t overlook to join our free weekly E-newsletter right here, the most recent 3D printing information straight to your inbox! You may as well discover all our movies on our YouTube channel.

*Cowl picture credit: NASA