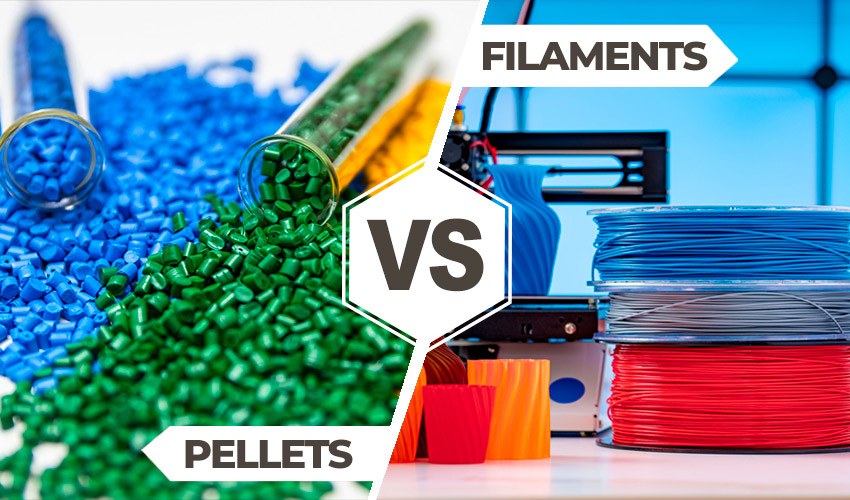

Plastics are no doubt probably the most broadly used materials households in additive manufacturing. Suitable with all kinds of processes, they provide a number of properties and traits to components, whether or not these are destined to be prototypes, tooling or end-use objects. Obtainable in lots of varieties – filaments, pellets, powders, resins – they meet the wants and necessities of producers in all sectors. Whereas we in contrast powders to plastic resins a couple of months in the past, it’s time to check out two different polymer households: filaments and pellets. What are their traits and functions? Which 3D printing processes are they suitable with? What producers are available on the market, and the way a lot do these supplies value? We inform you all about it on this new devoted article!

Filaments and pellets are two types of materials at the moment suitable with 3D printing, and though metallic and ceramic options can be found at present, we’ll be concentrating solely on plastics. To begin with, we have to return over the definition of a plastic pellet and a plastic filament. A pellet is a form of small ball 0.5 cm in diameter that may be melted, molded or extruded to make every kind of plastic objects. Plastic pellets are subsequently key within the chemical trade. They can be utilized in additive manufacturing with particular machines.

To make filament for 3D printers, you want plastic pellets (picture credit: Capifil)

Filament, alternatively, is a thermoplastic obtained by mixing plastic pellets or floor plastic scrap with a number of components. A filament extruder is required to realize the tube-like look. After a number of phases of cooling, the filament passes via a coiling machine to acquire a spool that may then be utilized by a 3D printer.

Traits and Properties of Filaments and Pellets

Plastics manufacturing is a large market, with figures rising in recent times by way of manufacturing, employment and funding. These plastics can take quite a lot of varieties once they depart the refinery: liquids, powders or pellets. In all instances, they’re then formed to supply every kind of components, whether or not by molding, injection, thermoforming or, after all, extrusion.

Turning first to industrial plastic pellets, it’s price noting that there are an enormous variety of them available on the market, providing a variety of properties and traits relying on their chemical composition. Also referred to as nurdles or pre-production plastic pellets, they’re outlined as “very small pellets of plastic (smaller than 5mm) that function uncooked materials within the producer of plastic merchandise”. They will also be completely different colours.

Industrial plastic pellets are a combination of the polymer itself and chemical components. A number of polymers are used on this course of, together with polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), polystyrene (PS) and PVC. Naturally, the mechanical and chemical properties of every plastic pellet differ significantly.

Plastic pellets are broadly out there available on the market (picture credit: DEKRA Industrial)

One of many benefits of using pellets in 3D printing is that they’re already utilized in extra conventional manufacturing applied sciences, comparable to injection molding. Which means when you use a professional materials in additive manufacturing, you should utilize the identical one when you change to injection molding, with out having to undergo a qualification stage. It is a appreciable benefit, not just for the manufacturing of “proper materials” prototypes, but in addition for the manufacture of completed components utilizing supplies already acknowledged by trade.

If we now flip our consideration to filaments, the manufacturing course of takes longer, because it entails remodeling plastic pellets into tubes able to being extruded. A number of phases are concerned: first, the moisture is faraway from the pellets. Subsequent, the pellets are melted in order that they are often handed via an extruder, which provides the filament its tubular form. As soon as shaped, the filament is cooled in appropriate baths. It’s then spooled to be used on a 3D printer.

Within the course of of remodeling pellets into filament, components are added, which inevitably alter the uncooked materials. When utilizing a filament to 3D print an element, an extra step is required to qualify the fabric. By way of suitable plastics, you’ll discover a number of kinds of polymer, from PLA to ABS, in addition to elastomers and high-performance polymers comparable to PEEK or PEI. Relying on the filament chosen, the half’s properties will differ: when you’re on the lookout for transparency, you’ll go for polycarbonate, whereas when you’re on the lookout for mechanical energy, you’ll select PEEK.

Please word that some plastics are harder to rework into filament because of their chemical composition, so that you’ll have a wider alternative of supplies when you go for pellet 3D printing.

The KIMYA filament manufacturing plant (picture credit: Hervé Boutet)

Suitable 3D Printing Processes

Whether or not you go for plastic pellets or filament, the popular printing course of is extrusion, or extra particularly fused deposition modeling (FDM/FFF) for filaments and Fused granulate fabrication (FGF) for pellets. The precept is mainly the identical: the plastic materials is heated after which handed via an extruder earlier than being deposited layer by layer on a platen to type the ultimate object. The distinction lies within the device used for extrusion.

Within the case of filaments, 3D printers use an extruder with a stepper motor and a toothed wheel to advance or retract the filament. On the finish of this feeder is a heating block which, as its identify suggests, heats the fabric. The fabric then passes via a nozzle, various in diameter between 0.4 and 0.8 mm, which strikes to deposit the filament on the print mattress. Relying on the fabric you’re utilizing, you’ll want a brass or copper nozzle, a heated chamber, a heated plate, and so forth. The thermoplastic will decide the kind of machine you want and your printing parameters.

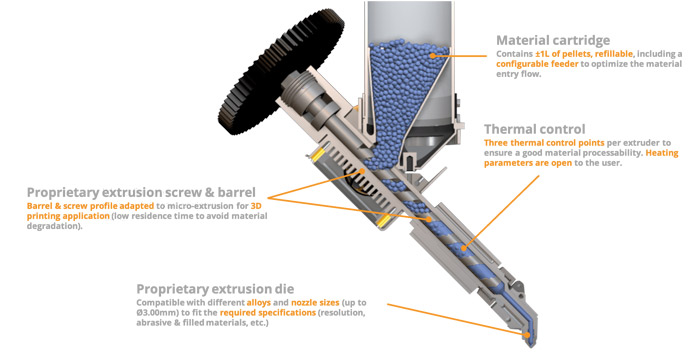

For pellets, the extrusion course of (FGF) is somewhat completely different: the 3D printer makes use of a hopper system to soak up the plastic beads and push them to the melting zone. The pellets are then softened and ejected by the nozzle, which might then deposit the fabric layer by layer on the printing plate. This nozzle can have completely different diameters, usually bigger than these used on FDM 3D printers that use filaments. Lastly, this kind of extrusion system will be put in on robotic arms to supply larger printing floor and adaptability.

The extrusion system for plastic pellets is completely different from that for filaments (picture credit: Pollen AM)

Using plastic pellets allows greater deposition speeds and bigger volumes to be achieved than with a filament. Then again, precision and backbone are much less essential. Pellet 3D printing is subsequently preferable for large-format components, because the filament spool doesn’t have to be modified, and the machine is able to extruding a bigger amount with out interruption.

It must be famous, nonetheless, that the pellet 3D printer can not shrink the fabric, which can lead to a larger stream of plastic via the nozzle than on an FDM machine. To interrupt the stream of fabric, the nozzle must be stopped or blocked. So it’s greatest to show to 3D filament printing to design extra complicated and detailed components.

Filament and Pellet Functions in 3D Printing

Total, the functions of 3D printing with pellets or filaments are fairly comparable: prototyping, tooling, completed components, the spectrum is large. However, as you’ll have gathered, there are a couple of key variations to keep in mind earlier than taking the plunge.

So far as filaments are involved, their versatility and availability available on the market imply that they can be utilized for all kinds of functions. They lend themselves effectively to the creation of modest-sized components, but in addition to initiatives requiring a sure degree of element and precision. Filaments are broadly used within the subject of speedy prototyping, enabling designers and engineers to create fashions and multiply checks to guage ideas earlier than remaining manufacturing. Relying on the properties of the filament in query, it’s potential to design components for the automotive, aeronautics, meals, medical and different industries. Some thermoplastics are hearth and smoke resistant; others are biocompatible; some are strengthened with carbon fibers for larger energy whereas remaining light-weight.

Steam armchair designed by Slicelab and printed with PETG pellets on the EXT 1270 Titan Pellet 3D printer

If we take a look at pellets, what is especially attention-grabbing is that it’s potential to create tailored formulations by mixing several types of plastic. This versatility opens the door to a mess of functions, not least within the healthcare sector, the place biocompatible supplies will be developed for the manufacture of custom-made prostheses and implants. Within the automotive sector, pellets are used to create custom-made components comparable to dashboard components, cable trays, engine covers and mechanical elements, rushing up the event course of and decreasing prices. They’re additionally in demand within the design sector for bigger furnishings and ornamental gadgets. Final however not least, additionally it is potential to make pellets from recycled supplies, thus selling the round economic system, a very essential idea in at present’s society. The identical recycled pellets can be utilized to supply filaments.

Lastly, as talked about earlier within the article, utilizing pellets in additive manufacturing is especially attention-grabbing for materials prototyping. Because the uncooked materials is similar in each 3D printing and injection molding, an operator can 3D print prototypes, submit them for testing and certification earlier than transferring on to mass manufacturing, with out having to undergo extra certification phases. This protects producers a substantial period of time.

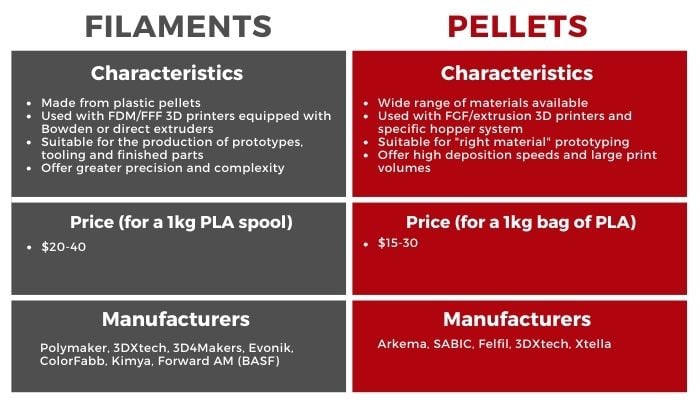

The Value of Supplies

Filaments are broadly out there available on the market and are most of the time inexpensive for newbies. It is because they’re offered in spool type, often 750 grams, which makes them simpler to handle and retailer. Costs differ in line with the kind of filament, however on the whole, you may get a spool of PLA, probably the most widespread supplies, for round 20 to 30 euros. Nonetheless, some extra particular filaments, comparable to versatile or composite filament, will be costlier, starting from 30 to 50 euros per spool. What’s extra, when you steadily print massive objects, the price of filaments can rise quickly.

Pellets, not like filaments, are usually offered in multi-kilogram baggage, which implies you should buy a big amount of fabric directly. This may symbolize a better preliminary funding, as costs for baggage of pellets can differ from 50 to 100 euros or extra, relying on the kind of plastic and the amount. Nonetheless, from a purely monetary standpoint, pellets usually win out over filaments. The worth per kilo of pellets is decrease than that of filaments, primarily because of the transformation course of required to create the latter. Then again, a person wishing to buy a small amount of plastic pellets might discover it troublesome to seek out the quantity required.

So remember the fact that, though the preliminary value of pellets could seem greater because of bulk buy, it could show extra advantageous in the long term for frequent 3D printing customers. This may after all rely in your wants and price range.

A spool of filament stays comparatively accessible (picture credit: La Nouvelle Ecole)

Filament and Pellet Producers on the Market

Within the 3D printing market, there are a mess of filament and pellet producers, every making their very own contribution to this fast-growing trade. As defined above, filaments are broadly prized for his or her ease of use and affordability. Corporations comparable to Polymaker, 3DXtech, 3D4Makers, Nanovia, ColorFabb and Kimya provide a variety of high-quality filaments, from PLA to PETG and ABS. The key chemists make a serious contribution to this trade, some having developed their very own filament manufacturers, like BASF or Evonik.

In terms of plastic pellets, the producers are kind of the identical chemical teams – Arkema and SABIC, to call however two. There are additionally gamers like Felfil, 3DXtech and Xtellar. Some have even specialised within the manufacturing of plastic pellets from recycled waste, such because the American firm re3D.

Lastly, on the subject of the producers of machines suitable with this kind of plastic, the selection is huge, significantly on the subject of filaments. There are conventional gamers comparable to Stratasys, UltiMaker and Zortrax. Increasingly more gamers are coming into this market, with workplace, skilled and industrial options. On the pellet facet, we are able to point out producers Arburg and Pollen AM, in addition to 3D Techniques, which acquired Titan Robotics in 2022, and AIM3D. The listing is certainly not exhaustive.

In conclusion, each kinds of plastic provide manufacturing benefits effectively suited to completely different manufacturing conditions. Ensure you use the correct materials to maximise the effectivity of your additive manufacturing course of!

Do you favor filaments or pellets? Tell us in a remark under or on our LinkedIn, Fb, and Twitter pages! Don’t neglect to enroll in our free weekly Publication right here, the newest 3D printing information straight to your inbox! You can even discover all our movies on our YouTube channel.