Nori bricks, which have been first fired within the Lancashire city of Accrington in 1887, rapidly turned legendary as the toughest brick ever produced. Their power, derived from the chemical properties of the native clay, enabled megastructures to stand up around the globe, together with the Blackpool Tower in 1894 and the Empire State Constructing in New York in 1930. Their identify is alleged to be a cock-up from once they meant to write down “iron” on the works’ chimney.

This 12 months a distinct, although equally pioneering, building materials is about to carry consideration to the city, which is 20 miles north of Manchester and whose most up-to-date declare to fame is being trash-talked in a 1989 advert for milk. On Constitution Road, on a patch of disused land owned by the council, there are plans to construct 46 net-zero-carbon properties, starting from single-bedroom flats to four-bed homes, all occupied by low-income households or army veterans. The properties can be made not from Nori bricks, however from 3D-extruded concrete. When the event is full, doubtlessly in late 2023, it is going to be the biggest printed constructing advanced in Europe.

“My grandad truly used to work on the brick manufacturing facility,” says Scott Moon, born-and-raised in Accrington, whose firm, Constructing for Humanity, is behind the Constitution Road mission. “Once I was younger he used to take me in there at night time and I used to trip on the again of the forklift. So, bless him, if he may see us now, about to start out concrete-printing homes in Accrington…”

You keep in mind 3D printing – also referred to as additive manufacturing – proper? You most likely learn an article round 2012 that predicted how each dwelling would quickly have a 3D printer that we’d use for all method of ingenious duties. OK, properly that didn’t occur. “No person’s going to be making bits for his or her washer when it breaks,” says Richard Hague, professor of additive manufacturing on the College of Nottingham. “Individuals making handles for his or her saucepans once they drop off? Nobody’s going to do this and also you’d be mad when you did. You’ll be able to simply order stuff from Amazon faster and get it delivered the subsequent day.”

However whereas dwelling utilization of 3D printers has not taken off, stealthily the expertise has been inveigling its method into our lives in different methods. Virtually all – 99% plus – customized listening to aids at the moment are 3D printed in acrylic resin, and have been for years. Additive manufacturing is extensively utilized in dentistry: tooth aligners, that are more and more taking the place of conventional wire braces, could be nearly inconceivable with out 3D printing. Adidas and Nike use the expertise of their footwear. There are 3D-printed elements on all new plane and in a rising variety of vehicles.

“What occurred 10 years in the past, when there was this large hype, was there was a lot nonsense being written: ‘You’ll print something with these machines! It’ll take over the world!’” says Hague. “Nevertheless it’s now changing into a very mature expertise, it’s not an rising expertise actually any extra. It’s extensively applied by the likes of Rolls-Royce and Normal Electrical, and we work with AstraZeneca, GSK., an entire bunch of various individuals. Printing issues at dwelling was by no means going to occur, however i t’s developed right into a multibillion-dollar trade.”

That’s no exaggeration: the 3D-printing market is forecast by Hubs, a market for manufacturing companies, to nearly triple in measurement by 2026, with a worth of $44.5bn. Building is without doubt one of the development areas. In 2018, a French household and their three kids turned the primary household to dwell in a 3D-printed dwelling. The four-bedroom bungalow in Nantes took 54 hours to print and price £176,000. Extra formidable buildings have adopted within the Netherlands, the US and Dubai. The Accrington mission has been made potential by latest developments in load-bearing printable concrete that performs properly, however can also be cost-effective.

“In very, very fundamental phrases, you’ve gotten a rig that sits onsite, over the place the home goes to be,” explains Dr Marchant van den Heever, a structural engineer who works for Dublin-based Harcourt Applied sciences (HTL), the development accomplice of Constructing for Humanity on the Constitution Road mission. “And you’ve got a material-delivery system. So that you combine up concrete, which you feed into the printhead. And basically this printhead is sort of a gigantic cake-icing machine that extrudes concrete, one of the crucial strong supplies on the earth.

Should you think about a ebook, every web page within the ebook is a layer of concrete,” van den Heever provides, “and these consecutive layers stack on high of each other and that kinds your superstructure.”

The cake analogy is a useful one. Early 3D-construction initiatives usually have a ribbed, Michelin-Man exterior, just like the piped end of a rushed showstopper problem on Bake Off. However the sophistication of the end is bettering quick and slick 3D-printed buildings usually now seem in tales for the likes of design web site Dezeen and Architectural Digest. However what actually excites corporations comparable to Constructing for Humanity and HTL are the potential financial savings and efficiencies the brand new expertise provides. Constitution Road has a projected finances of £6m, an estimated 25% price discount in opposition to comparable building. Will probably be made with sustainable, usually recycled supplies in what they hope can be half the positioning time – 101 working days, as a substitute of greater than 12 months.

“To be cost-competitive from the get-go is sort of unprecedented for an rising expertise,” says Justin Kinsella, an architect who based Harcourt 20 years in the past and who’s making his first foray into 3D-printed buildings. “We’re simply excited to truly have individuals come on web site, slam the door, the wall doesn’t wobble. Kick the wall, that doesn’t transfer. The roof is there. Change the lights on, that’s proof and other people will then, I believe, be astounded by it.”

First described in sci-fi writing within the Fifties, 3D printing turned a really fundamental actuality within the Nineteen Eighties. The core rules stay the identical at this time: an object is created layer by layer – therefore additive – from the bottom up. (Think about sedimentary rock forming, simply actually, actually quick.) This is perhaps finished by bodily extruding a cloth, as within the building mission in Accrington, or it might be computer-guided laser beams that make layers, which will be as skinny as a human hair, by melting powders of metallic, plastic or different supplies. One of many nice, instant benefits of additive manufacturing is that you just solely print what you want. This contrasts with machining a lump of metallic, for instance, the place you would possibly carve away most of it, which is then wasted or must be recycled.

Within the early years, although, 3D printing was costly, sluggish and vulnerable to gaffes. Solely not too long ago has the expertise developed to beat a few of these flaws. Additionally, there was a stark realisation that 3D printing just isn’t going to be a magic bullet. “I’d come throughout like an enthusiastic baby and I’m actually enthusiastic,” says Hague. “However I’m super-realistic about what can and may’t be finished. And so that you’re not going to be doing every little thing with additive.”

One of many areas of pleasure a decade in the past was the thought of 3D printing meals. On this imaginative and prescient of the long run, we’d come right down to breakfast to a freshly printed croissant or pop some dough within the machine, faucet a number of buttons and are available again to “home made” ravioli. The brand new merchandise would additionally tackle one of many nice challenges of our age – that one-third of the meals produced on the earth, about 1.3bn tonnes, is wasted.

It was this statistic that introduced 26-year-old Elzelinde van Doleweerd, a graduate in industrial design from the Eindhoven College of Expertise within the Netherlands, into the sphere. She started experimenting with bread, fruit and greens, essentially the most generally spoiled meals in northern Europe, to see if dehydrating them and altering them into lovely shapes may give them a second life. This led to a six-month placement in 2021 within the check kitchen on the Copenhagen restaurant Alchemist, which is presently ranked 18th on the world’s 50 greatest checklist.

On the finish of her stint at Alchemist, van Doleweerd had refined a beetroot and carrot “tartelette” that was served on 3D-printed petals created from chitosan, a sugar derived from the outer pores and skin of shellfish, and garnished with edible flowers. It appears gorgeous – “It’s a very good vibe!” confirms van Doleweerd – however has but to make it on to the menu at Alchemist due to the difficulties of manufacturing it underneath strain at each service.

For van Doleweerd, who now works within the meals lab at Restaurant De Nieuwe Winkel within the Netherlands, which has been rated the world’s greatest plant-based restaurant, it’s arduous to think about 3D-printed meals coming into the mainstream quickly. “I believe it’s fairly specialised,” she concedes. “The most recent growth we see in meals and residential cooking is that it shouldn’t take that a lot time and we don’t wish to putthat a lot effort into it. Possibly if now we have an awesome growth the place you’ll be able to simply begin speaking to your printer, like whenever you get off the bed, ‘Please put together breakfast for me!’ We’ll see, however I don’t actually imagine in it but.”

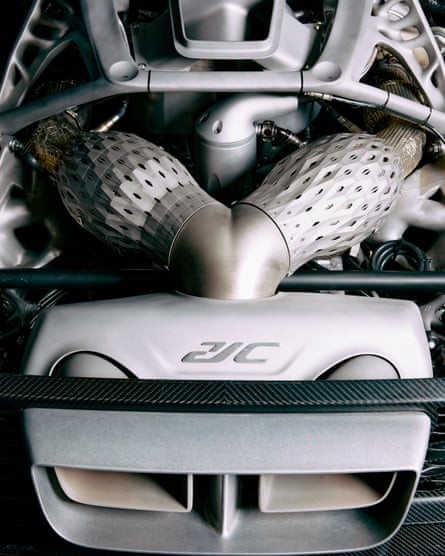

The place 3D printing appears to thrive, Hague notes, is in customisation and light-weight design. “You can also make super-complex geometries that you just simply can’t do some other method,” he says. One firm profiting from the geometric freedom of the expertise that is Czinger, the Los Angeles-based automobile producer. Proper now, Czinger solely provides one mannequin, the 21C, however it’s a head-turner: a hypercar with a high pace of 253mph, a 0-60-time of underneath 2 seconds, and a price ticket of $2m. Components of vehicles – particularly prototype elements – have been 3D printed for some time, however the 21C goes a lot additional. “It isn’t actually a automobile in any respect,” wrote Jack Rix, editor of BBC’s Prime Gear Journal in his evaluate of the 21C, “it’s a demonstrator for what’s potential with digital design and 3D printing.”

Czinger is the identify and the imaginative and prescient of its founders, dad Kevin Czinger and his son Lukas, 28. Their firm has greater than 150 workers and so they have been recruited from Ferrari and F1 groups but in addition Apple and SpaceX.

“We each love driving, we each wished to make a automobile that will take our breath away,” explains Lukas Czinger on a 7am (for him) video name. “And positively having that automobile on the monitor, it appears like nothing I’ve ever pushed, nothing my dad’s ever pushed, the downforce, the seating place, the pure energy. It’s every little thing we dreamed of. It’s wild in the most effective of how. It’s like being within the cockpit of a fighter jet, however as a substitute of being within the air, you’re someway nonetheless planted to the bottom. You don’t absolutely perceive physics any extra.”

You would possibly legitimately marvel how a lot relevance a $2m hypercar has to something in the true world. However Czinger makes elements for at the least eight extra mainstream automotive manufacturers – the one one they’re allowed to call in the meanwhile is Aston Martin. 3D-printed elements will be lighter, extra aerodynamic and doubtlessly stronger, Lukas Czinger argues, and all of those developments have a possible environmental profit, as vehicles grow to be extra gas environment friendly. “Within the subsequent 5 years, you’re going to start out seeing it on on a regular basis vehicles,” he predicts. “And within the subsequent 10 years, you’re going to principally have seen it change most of casting and extruding and stamping. So, yeah, I absolutely imagine it’s the future.”

I ask Prime Gear’s Rix if he buys Czinger’s declare that the 21C is a “traditionally vital car” that may basically change the automobile trade. “Each automobile producer is frequently trying to enhance packaging, scale back weight, increase gas effectivity, but in addition discover methods to construct their vehicles to a better high quality and for much less,” Rix replies. “Czinger claims to have solved all these issues in a single fell swoop.” As for the way influential this expertise can be: “It is just a matter of time earlier than all new vehicles have some 3D-printed elements.”

We’ve been right here earlier than, after all: 3D printing will save the world! So why imagine it now? There may be rising proof that the hype, this time spherical, may not be overstated. Not all of those developments will contact our lives instantly. Nasa and all space-exploration corporations already use additive processes to make elements for his or her rockets. However they’re additionally investigating the challenges that may come up as soon as they land on the Moon or Mars . They won’t be able to hold all of the assets with them, in order that they have to search out strategies for building and offering meals: maybe utilizing the directed vitality from the solar and the supplies they may discover on the bottom. Nasa funds one mission that’s trying into recycling the urine, faeces and breath of astronauts on lengthy journeys to make meals and plastics for 3D printing.

However, if it hasn’t already, additive manufacturing will quickly contact – and even, possibly, prolong – all of our lives. The American firm Stryker makes use of 3D printing to provide advanced orthopaedic implants that wouldn’t in any other case be potential. Within the US final 12 months, a girl’s ear was reconstructed with an implant of 3D-printed dwelling tissue. A human lung scaffold was offered at a convention in San Diego final summer season, presumably essentially the most difficult object ever created utilizing additive manufacturing.

The College of Nottingham’s Richard Hague is presently working with GSK and AstraZeneca on the 3D printing of “biopills” – a number of medicines in a single capsule which are bespoke to every affected person, which is able to dramatically simplify what you should take and when, particularly for aged individuals. “Compliance is a large concern: you’ve bought all these medication, individuals simply don’t take them,” says Hague. “These are large potential advantages that folks can perceive.”

That is the place the promise of 3D printing turns into irresistible – the place the expertise clearly makes life easier or higher, with no further expense for the patron. In Accrington, Constructing for Humanity desires to place individuals on the housing ladder who in any other case would by no means have the ability to afford it. One of many homes has been reserved for Mark Harrison, 44, a veteran from the city who obtained a medical discharge from the Military in 2001 after two excursions in Bosnia, and was later recognized with PTSD.

Harrison estimates he has lived in 20 homes within the final 20 years, however hopes Constitution Road will present stability for him and his three kids. He’s additionally being educated up by HTL to make use of the printing equipment – he may have a brand new job in addition to having a hand in constructing his new dwelling.

“All these years I’ve been going to remedy and I’m making an attempt my hardest to kick on and get higher,” says Harrison. “The home could be the icing on the cake. It’ll give me someplace to place down some roots: one thing for my children’ future and for me to remain in the identical place for greater than two minutes. It’s been tough, however yeah, it’s an unimaginable alternative. It simply looks like every little thing has lastly fallen into place.”