As we all know, within the manufacturing business, additive and subtractive applied sciences might be key assets when used complementarily. Nevertheless, in lots of sectors, there are nonetheless obstacles to the mixing of 3D printing as a manufacturing technique, whether or not because of prices, lack of awareness or lack of certified professionals. For these causes, SolidCAM, a number one developer of CAM options, goals to ease the adoption of additive manufacturing. That is of explicit curiosity in CNC machine retailers, which focus on machining strategies, the place the advantages that additive techniques can carry are sometimes missed. Fortunately, SolidCAM’s partnership with Desktop Metallic has made additive manufacturing extra accessible to machine retailers.

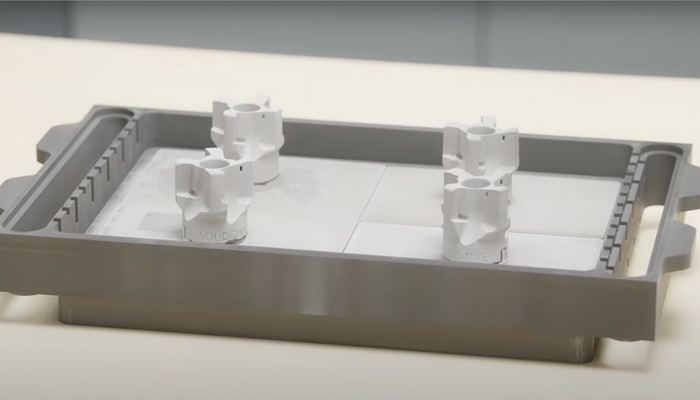

A CNC machine store is outlined as an space the place extremely complicated subtractive manufacturing strategies are used. They typically use CNC machine instruments and chopping applied sciences to fabricate steel or plastic components, in addition to different supplies. Due to this fact, for them, it’s fascinating to contemplate incorporating additive manufacturing into manufacturing, together with for prototyping and end-use components. Moreover, as 3D printing turns into more and more necessary in low and medium quantity manufacturing, it’s a key software for corporations to be aggressive available in the market. That is the place an answer like SolidCAM is available in. At the side of Desktop Metallic and its Metallic Binder Jetting know-how, adoption is now a lot simpler. Desktop steel’s Store System is the primary additive manufacturing platform that brings steel 3D printing to machine retailers. Let’s take a look at what this course of is all about and what advantages it brings to manufacturing corporations.

The combination of additive manufacturing allows corporations to be extra aggressive

Additive Manufacturing in CNC Machine Retailers

One of many important points that machine retailers encounter when exploring additive manufacturing is that suppliers don’t admire the calls for and necessities of the surroundings. Options are wanted that may execute half manufacturing shortly and at a suitable value. As a result of SolidCAM works with machines retailers every day, offering them with CAM software program for greatest programming of their CNC machines, SolidCAM understands the machine store wants, with the intention to information them to a course of that is smart and is value efficient. Each SolidCAM and Desktop Metallic acknowledge that adoption includes far more than merely inserting a steel 3D printer on the store ground. You will need to have a radical understanding of how you can create an optimum in-house additive manufacturing infrastructure for manufacturing and its synergy with subtractive applied sciences.

To do that, a variety of components should be thought of, similar to designing for additive manufacturing or choosing the proper functions for 3D printing. It is usually important to know how you can handle the complete steel additive manufacturing course of, from file preparation to printing, sintering and subsequent CNC machining post-processing. Consultants additionally stress the significance of optimizing the complete course of and making certain that the very best manufacturing and high quality requirements are met. SolidCAM’s information, along with Desktop Metallic’s 3D printing techniques, helps to simplify a posh course of with the intention to improve productiveness and half yield, with restricted operator involvement.

SolidCAM helps corporations undertake applied sciences from begin to end

Finish-to-Finish Know-how Integration

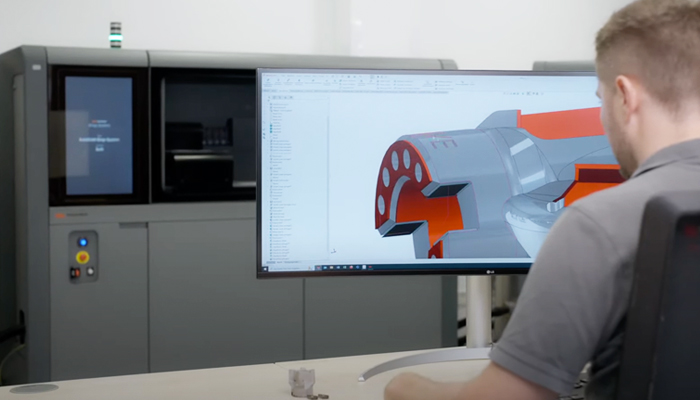

As soon as a person has determined to undertake 3D printing, first it’s essential to begin with some preliminary 3D design steps. SolidCAM’s built-in strategy to CAD/CAM supplies a major benefit on this regard. Its CAM performance might be run inside Solidworks and Autodesk Inventor CAD modeling software program, each of which have design capabilities for additive manufacturing. Thus, customers can apply the very best design instruments and leverage the identical 3D mannequin for CNC programming capabilities, similar to iMachining and Superior Mill-Flip. As well as, the corporate can be growing a brand new module for hybrid machines the place 3D printing and machining happen on the identical platform. This aligns with Desktop Metallic’s holistic strategy to additive manufacturing, from creating proprietary steel powders to sintering components.

In each additive and subtractive manufacturing strategies, approach is as necessary a facet as know-how. To cowl each and additional assist machine retailers, SolidCAM has created facilities of excellence that combine 3D printing and CNC machining. The aim? To point out how you can implement additive manufacturing, in addition to produce components for corporations that aren’t able to tackle the complete dedication. Dr. Emil Somekh, founder and CEO of SolidCAM, says, “By way of combining the 2 applied sciences, corporations can remedy complicated engineering issues in new and revolutionary methods. Metallic 3D printing will nonetheless want post-processing with CNC machining to make sure the components are to the end specs the shopper requires. SolidCAM is positioned because the chief in CAM options, adapting its software program know-how to successfully post-process the rising market of additive components.”

It’s clear that SolidCAM’s manufacturing experience mixed with Desktop Metallic’s 3D printing options are serving to many corporations within the adoption of additive manufacturing. Reinforcing this place, Somekh concludes, “SolidCAM views additive manufacturing as a complement to our 24,000 CNC subtractive manufacturing clients worldwide. The power to print complicated steel components, with pace and repeatability, is now inside attain of even the smallest job retailers and we have now dedicated to turning into a number one useful resource on this area for our SolidCAM CNC clients.” Extra info might be discovered on the SolidCAM web site HERE.

What do you consider the mixing of AM into CNC machine retailers? Tell us in a remark under or on our Linkedin, Fb, and Twitter pages! Don’t overlook to enroll in our free weekly E-newsletter right here, the most recent 3D printing information straight to your inbox! You may also discover all our movies on our YouTube channel.

*All Photograph Credit: SolidCAM