3D printing is turning into more and more widespread in all industries the place customization, design and efficiency meet. The flexibility to create advanced buildings in addition to to make use of 3D printing for speedy prototyping and thus to check supplies and properties shortly and inexpensively, makes it appropriate for sectors resembling automotive, aerospace or sports activities. The biking business, for instance, advantages from additive manufacturing for the creation of elements, prototypes, but in addition end-use elements that match clients’ wants or are even custom-made for athletes’ our bodies. The case of the corporate Ursus, which turned to on-line 3D printing service Weerg to make a {custom} handlebar, is an effective instance.

In reality, corporations that want to provide small and medium-sized, custom-designed elements briefly runs encounter fairly just a few difficulties after they flip to conventional manufacturing strategies. Injection molding doesn’t meet such calls for due to the lengthy lead instances and the big value of molds. Additive manufacturing, however, is the perfect answer in such instances. Many corporations are due to this fact turning to 3D printing service suppliers to optimize time and sources, reaching higher outcomes when it comes to each efficiency and optimization of manufacturing processes.

An operator on the headquarters of additive manufacturing service Weerg (photograph credit: Weerg)

The Mixture of Weerg’s On-line Companies and HP Multi Jet Fusion

Inside this context is an all-Italian success story, born out of the collaboration between the corporate Ursus, which has been energetic for greater than 50 years within the subject of engineering and bicycle elements, and the net manufacturing service Weerg. The 2 corporations collaborated within the creation of the Magnus H.02 handlebar with HP’s Multi Jet Fusion expertise, offered by Weerg. Primarily based in Scorzè (Venice), Weerg is a web based manufacturing service providing each CNC and 3D printing options, with 100% in-house manufacturing. By way of additive manufacturing, the corporate presents FDM, SLA and HP Multi Jet Fusion (MJF) applied sciences, proudly owning the world’s largest fleet of MJF 3D printers. Ursus due to this fact turned to Weerg with the intention to first take a look at after which produce the brand new Magnus H.02 handlebar.

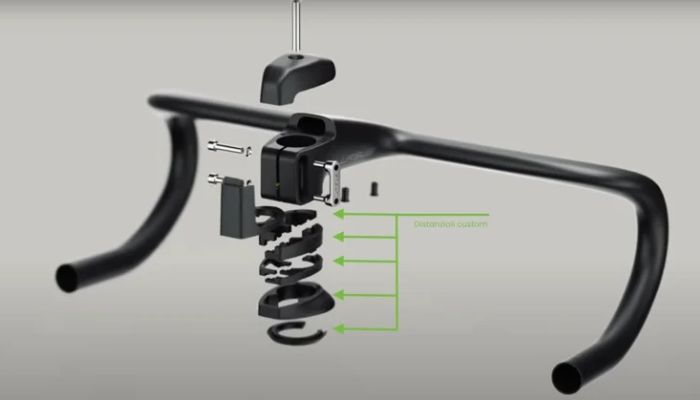

As a famend firm within the biking world, Ursus is understood for its drive for innovation by analysis and design of its merchandise. Certainly, the Magnus H.02 handlebar was a problem for Ursus’ designers, as it’s a handlebar for racing bicycles that Ursus labored exhausting on to mix lightness, ergonomics and aerodynamics. Throughout the design of the handlebar, the objective was to make an attachment system that will match completely on completely different frames.

“Typically, when some bicycle producers contact us to place considered one of our merchandise on their frames, they supply us with completely different sizes from challenge to challenge. Subsequently, our objective is to create {custom} options in order that we will match our product completely to every body,” defined Matteo Cortese, product designer at Ursus.

Photograph Credit: Ursus/Weerg

Subsequently, to adapt the Magnus H.02 handlebar, the answer was to create completely different spacers that will regulate the peak of the attachment on the completely different frames. Given the low variety of adaptation copies and the necessity for personalization, using MJF expertise offered by Weerg offered the perfect answer. MJF expertise is in actual fact some of the enticing when it comes to time and price optimization, presenting huge benefits when it comes to flexibility and skill to course of all kinds of advanced geometries in comparison with different additive manufacturing applied sciences. It additionally permits the mechanical properties of the fabric to stay intact, making it appropriate for this sort of software.

The Manufacturing Technique of the Magnus H.02 Handlebar From Ursus

The manufacturing course of for the Magnus H.02 handlebar started for Ursus designers with turning to Weerg’s on-line platform to know the feasibility of the design. Being a completely on-line service, Weerg makes it straightforward and intuitive to enter 3D recordsdata, specs on supplies, finishes, and supply time in a single interface and obtain a free quote in seconds. By way of supplies, Weerg’s platform permits customers to decide on, for instance, for 3D printing from quite a few polymers together with resin, polypropylene, PEEK, ABS, and nylon. Weerg then developed along with HP the modern PA 12 White for MJF expertise, amongst others.

Ursus’ design was then submitted after which analyzed internally by a Weerg engineer, who assisted Ursus within the manufacturing of the handlebar. The flexibility to have a specialised engineer devoted to your challenge is undoubtedly an added worth as a result of it means that you can mix the effectivity of on-line service with the experience and human help typically wanted to deliver tasks to a profitable conclusion.

Weerg’s HP MJF machine farm (photograph credit: Weerg)

As well as, the benefit of getting 100% in-house manufacturing allowed Weerg to shortly ship the primary handlebar fashions for testing by Ursus designers. Matteo Cortese added, “By means of MJF expertise, Weerg allowed us to make glorious completed elements with good isotropic mechanical properties. On the positioning, we have been capable of order and obtain in about ten days the few thousand items we wanted for the challenge.”

Within the particular case of Ursus, having the ability to use MJF expertise for speedy prototyping of the handlebars was a breakthrough for the designers, who have been capable of take a look at the mechanical properties of the handlebars shortly and inexpensively, modifying and customizing them occasionally till the ultimate product was obtained. As soon as the exams have been completed, they have been then capable of request the mandatory items of the completed product. In accordance with the corporate, using the HP MJF expertise offered by Weerg saved as much as 20 instances the out there funds and improvement time, confirming Additive Manufacturing as the perfect manufacturing methodology for efficiency and {custom} elements. Study extra about Weerg and HP MJF expertise HERE.

What do you concentrate on using MJF expertise in Weerg’s collaboration with Ursus? Tell us in a remark under or on our LinkedIn, Fb, and Twitter pages! Don’t overlook to enroll in our free weekly Publication right here, the newest 3D printing information straight to your inbox! It’s also possible to discover all our movies on our YouTube channel.

*Cowl Photograph Credit: Ursus/Weerg