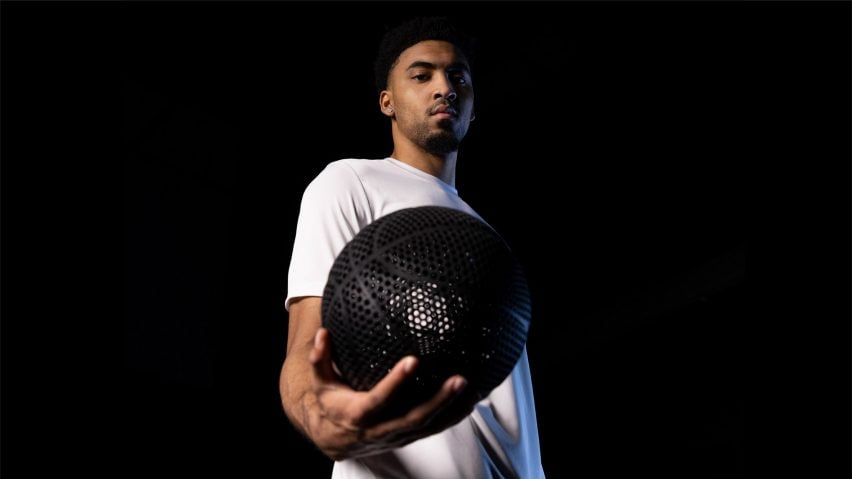

Sports activities gear producer Wilson has launched a prototype 3D-printed airless basketball that, in contrast to conventional balls, doesn’t must be inflated.

Constituted of an elastomeric polymer developed by Wilson, the airless ball has a see-through lattice construction with hexagonal holes that permit air to cross via it.

Though printed as one strong piece, the design options “seams” and eight panels that reference the design of conventional basketballs.

In accordance with Nadine Lippa, Wilson’s lead engineer on the undertaking, the corporate aimed to develop a ball that performs the identical as typical basketballs in measurement, weight and bounce however doesn’t must be inflated.

“My boss, Kevin Krysiak, initially charged me with reinventing the basketball,” Lippa advised Dezeen.

“One of many parameters or attributes that we felt may very well be improved upon is the truth that all inflatable balls ultimately go flat, so the impetus for this was creating an airless ball that does not require the usage of an air pump or a needle – it is only a single piece of kit that you would be able to simply exit and play.”

Wilson collaborated with manufacturing firm EOS to provide the ball, which was made utilizing the selective laser sintering (SLS) technique of additive manufacturing.

The strategy concerned utilizing lasers to fuse layers of polymer powder into the 3D design, which was then faraway from the encircling extra powder, sealed and dyed black.

“I feel with quite a lot of 3D printing you may make a sphere however to make one thing that appears and seems like a basketball actually simply requires the following stage,” stated Lippa.

In accordance with Lippa, probably the most difficult side of growing the airless ball was making certain it bounced equally to different basketballs.

“One of many largest challenges of the undertaking was discovering one thing that rebounds to the anticipated top that does not have air in, as a result of the inflated ball actually depends on its air stress to generate rebound,” Lippa defined.

“We put our 3D-printed ball via testing however we had been nonetheless not fairly glad with the sturdiness side so we additionally hit the ball with a baseball bat,” she continued.

“We had been actually happy to see that we weren’t in a position to actually harm it, even in that aggressive of a situation.”

By creating an airless ball, Wilson aimed to eradicate deflating points brought on by blunt pressure, manufacturing defects or air escaping via the valve over a protracted time frame.

The airless design additionally overcomes contraction in inflated balls brought on by altering environments and temperatures.

“When you’ve got the identical quantity of air inside an inflated ball and then you definitely go in a chilly setting, the contraction of the air causes the ball to look or play prefer it’s flat,” Lippa defined.

The ball prototype was launched in February at this yr’s NBA All-Star Weekend, the place members of the general public had been invited to play with it. Wilson is endeavor additional analysis earlier than formally releasing it as a product.

Different basketball-related designs which were featured on Dezeen embody Nike basketball trainers with self-lacing know-how and a basketball-shaped bottle designed by Hennessy to mark NBA’s seventy fifth anniversary.

Photographs and movies courtesy of Wilson Sporting Items Co.