These days nearly every part is being 3D printed, so why ought to structure be an exception? Many architectural corporations are adopting 3D printing as their most popular method for constructing constructions. And 3D-printed structure is slowly however certainly gaining lots of recognition and momentum. And I imply, no surprise, it has a ton of advantages! It’s a easy, environment friendly, and revolutionary method that lowers the dangers of errors, and in addition manages to save lots of time. 3D printing eradicates lots of tedious steps through the building course of and simplifies it.

Japanese building startup Serendix created a preferred tiny proof-of-concept final 12 months, and it was as much as code for Japanese earthquakes and European insulation requirements. And not too long ago they unveiled ‘Fujitsubo’ – a small dwelling priced at 5.5 million yen or round $37,600!

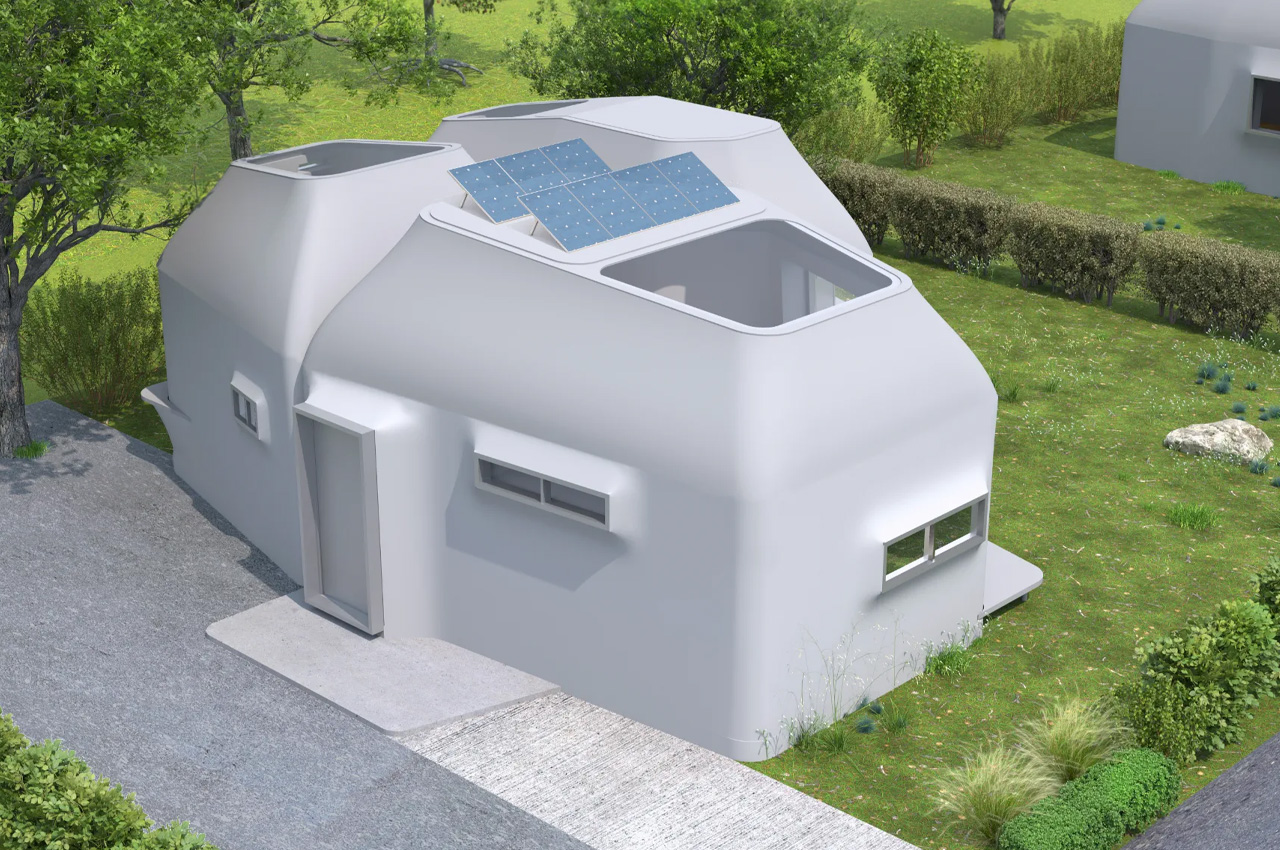

Designer: Serendix

Dubbed Fujitsubo or “the barnacle”, the compact dwelling occupies solely 538 sq. toes, which is fairly small compared to the common new American dwelling, which is 5 instances bigger. This 3D-printed dwelling options one bed room, one lavatory, and an open lounge linked to a kitchen…and it solely prices as a lot as a automotive! The house is right for a pair or one particular person. You possibly can contribute the dimensions of the house to the economical price ticket, which isn’t discovered within the US since native guidelines require minimal sizes for homes and much, and the price of land makes it nearly unattainable for builders to create smaller houses.

The roof is made from panels which are minimize by a pc numerical management (CNC) machine, during which pre-programmed software program controls the motion of manufacturing unit instruments and equipment. Serendix mentioned it took 44.5 hours to print and assemble the house. Since 3D-printed building isn’t a possible possibility for populated and dense city areas, as there isn’t a lot further land out there there, and even when there may be, it isn’t a cost-effective possibility, Serendix has determined to concentrate on constructing in small cities with an ample quantity of empty area out there.

“Within the automotive trade 40 years in the past, the worth discount of merchandise started resulting from innovation of the manufacturing course of utilizing robots. We imagine that the 3D-printed home is the start of the entire robotization of the housing trade,” Serendix mentioned in an announcement. The corporate is at present utilizing 5 printers to construct their houses (50 per 12 months) however by subsequent 12 months they plan so as to add twelve extra printers and construct nearly 850 houses yearly!