Czinger claims that it might probably transmit extra torque than some other gearbox in its weight class

10 hours in the past

by Sebastien Bell

Topology optimization is quickly gaining recognition on the earth of engineering, significantly in 3D printing, and is understood for its distinct, virtually organic-looking shapes. Now, one automobile firm is profiting from this know-how to push the boundaries of what’s attainable.

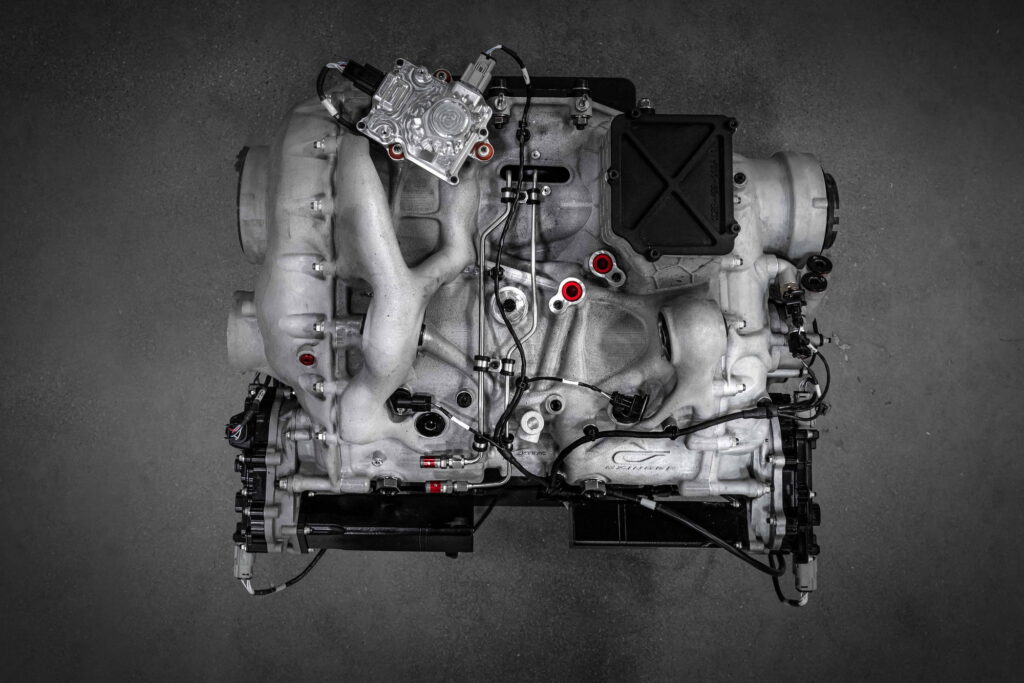

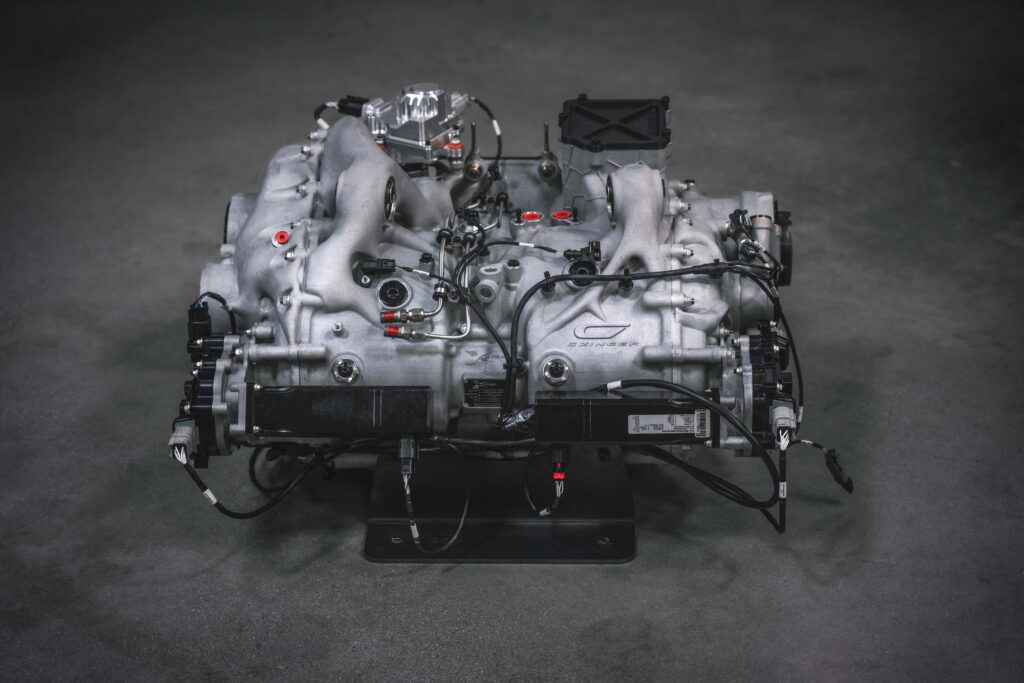

American maker Czinger Automobiles introduced this week that, with the assistance of Xtrac, will probably be the primary automaker on earth to incorporate a 3D printed, topology-optimized transmission into its car.

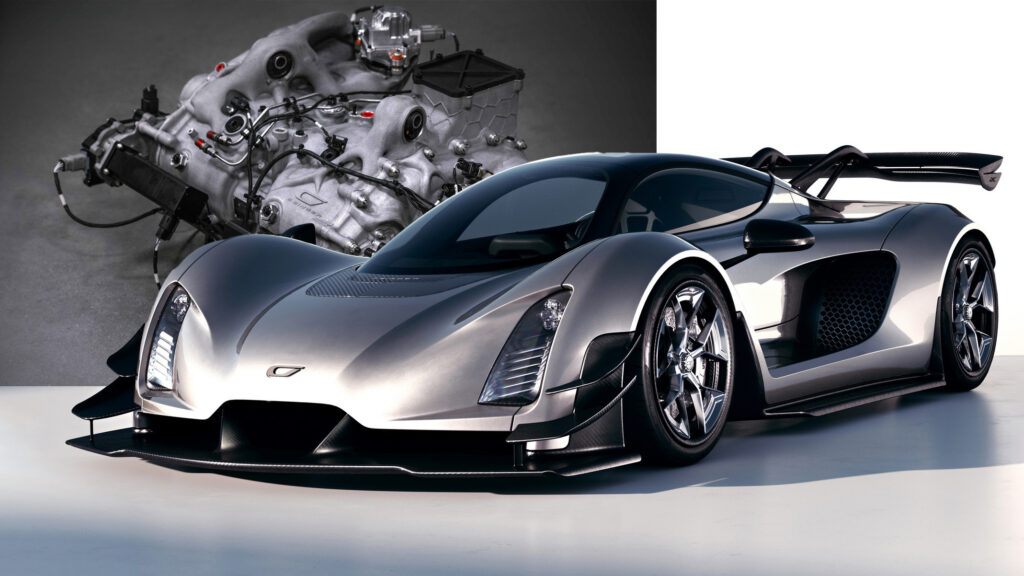

The 21C, unveiled in 2021, boasts essentially the most power-dense powertrain on the planet, in accordance with Czinger. It’s composed of a 2.9-liter, twin-turbocharged, flat-plane crank V8 that may rev as much as 11,000 rpm, in addition to a pair of electrical motors that flip the entrance wheels. Total, this configuration gives a powerful 1,233 horsepower (1,250 PS / 919 kW).

Learn: Czinger 21C Destroys Circuit Of The Americas Manufacturing Lap Report By 6 Seconds

That’s quite a lot of energy for a transmission to cope with and, in an effort to maintain weight low, the automaker has turned to topology optimization. This new 3D printed aluminum transmission permits for the best torque transmitted per mass of drugs case on any street-legal car on the earth, the automaker claims.

To create the automated, seven-speed, semi-sequential gearbox, it turned to Xtrac, which has been making motorsport transmissions and differentials since 1984.

commercial scroll to proceed

“What our Xtrac engineers have achieved in tandem with Czinger and Divergent is groundbreaking,” stated Adrian Moore, Xtrac’s CEO. “It has been extraordinarily fascinating and really stimulating for our engineers working intently collectively to convey this leading edge innovation to life.”

The transmission boasts sub-100 millisecond shifts for optimum efficiency. That pace can also be helpful for consolation, although, as, together with the twin-barrel gear actuation, it permits the facility to switch seamlessly from the electrical entrance wheels to the combustion engine-powered rear wheels.

“We’re proud to staff Czinger’s world-class engineers with these at Xtrac; collectively, we have now developed an unbelievable, trade first, gearbox that’s really on the pinnacle of efficiency,” stated Lukas Czinger, the automaker’s co-founder. “We are able to’t wait to shatter extra monitor data as we make the most of this method within the 21C”