Researchers on the Korea Electrotechnology Analysis Institute (KERI) have achieved a groundbreaking milestone within the realm of superior show expertise. Dr. Jaeyeon Pyo’s workforce at KERI efficiently developed the world’s first 3D printing expertise able to integrating clear shows and augmented actuality (AR) gadgets, impressed by the fascinating color-changing talents of chameleons and the colourful hues present in peacock feathers.

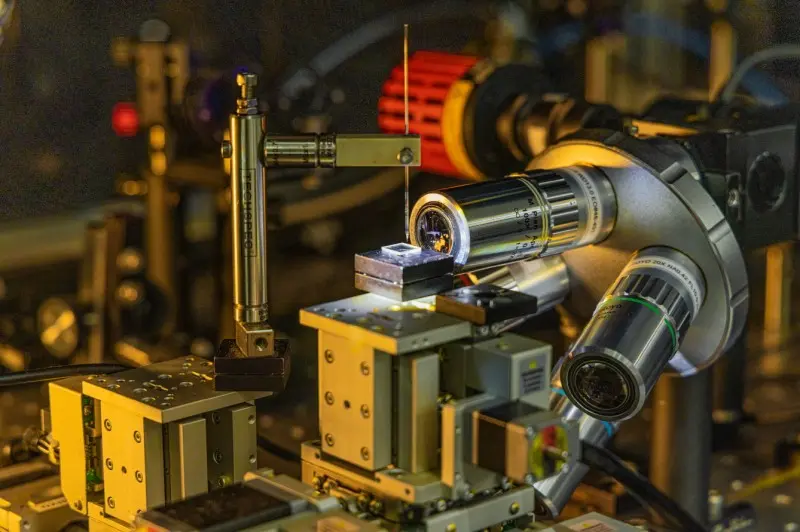

The important thing innovation lies within the implementation of a three-dimensional diffraction grating, exactly controlling the trail of sunshine utilizing nanoscale 3D printing expertise. This expertise capitalizes on the precept of structural coloration noticed in nature, the place gentle interacts with microstructures on the wavelength stage. This diffraction phenomenon leads to distinctive colours often known as ‘structural coloration,’ as seen within the pores and skin of chameleons and the interior microstructure of peacock feathers.

A diffraction grating is a tool with frequently organized microstructures, particularly designed to regulate the diffraction of sunshine. By shining gentle on this grating, the mirrored gentle disperses into completely different paths primarily based on its wavelength, producing vivid structural colours or spectra. Importantly, this 3D printing expertise allows exact gentle management for coloration with out the necessity for dyes.

Reaching such excessive precision in gentle management required the event of a really effective diffraction grating. KERI’s nanoscale 3D printing expertise, broadly thought to be the very best on the earth, made this doable by means of a novel strategy referred to as ‘lateral printing.’ The lateral printing technique includes the 3D printing nozzle transferring akin to stitching to print high-density nanowire diffraction gratings with the specified bridge-like form.

The implications of this technological breakthrough are huge. The clear nature of the diffraction grating opens up quite a few potentialities for future purposes, together with clear shows in sensible home windows, mirrors, and heads-up shows in vehicles. Moreover, AR gadgets, which already make the most of diffraction gratings, can additional profit from this expertise. The diffraction grating’s potential to emit completely different colours relying on deformation additionally makes it useful in mechanical engineering and biomedical purposes the place deformation detection is crucial. Moreover, this expertise serves as a robust device for optical physics analysis.

Dr. Jaeyeon Pyo emphasised that this 3D printing expertise allows exact implementation of desired structural coloration in particular places with out limitations relating to substrate supplies or shapes. This breakthrough liberates show gadgets from their formulaic ‘Type-Issue’ constraints, fostering form diversification and new design potentialities.

The analysis carried out by Dr. Pyo’s workforce was acknowledged for its excellence and featured as a canopy article in ACS Nano, a prestigious journal in supplies science printed by the American Chemical Society. With a powerful JCR Affect Issue of 17.100, putting it within the prime 5.7% of its discipline, the examine highlights the importance and potential impression of this technological development.

Having accomplished the patent software course of, KERI expects this achievement to garner appreciable consideration from firms within the show trade. The institute goals to facilitate expertise switch by figuring out companies that would profit from this cutting-edge 3D printing expertise.

It’s price noting that KERI is a government-funded analysis institute underneath the Nationwide Science and Know-how Analysis Council of the Ministry of Science and ICT. The analysis resulting in this breakthrough was carried out as a part of KERI’s primary undertaking, ‘Growth of 4D printing expertise for circuit/housing built-in gadgets.’ Moreover, Dr. Jaeyeon Pyo holds an adjunct affiliate professor place on the College of Science and Know-how (UST), additional reinforcing the institute’s dedication to analysis and training within the discipline of expertise.

Reference

Bae, J., Yoo, C., Kim, S., Ahn, J., Sim, H. H., Kim, J. H., Kim, J. H., Yoon, S.-Y., Kim, J. T., Seol, S. Okay., & Pyo, J. (2023). Three-Dimensional Printing of Structural Coloration Utilizing a Femtoliter Meniscus. ACS Nano, 17(14), 13584–13593. https://doi.org/10.1021/acsnano.3c02236