In a brand new examine, North Carolina State College researchers demonstrated that it is doable to make carbon dioxide seize filters utilizing 3-D printing. Particularly, they printed a hydrogel materials that may maintain carbonic anhydrase, an enzyme that speeds a response that turns carbon dioxide and water into bicarbonate.

The findings, revealed within the journal Gels, counsel 3-D printing might be a quicker, extra versatile technique of constructing filter designs.

“This manufacturing course of, utilizing 3-D printing, makes the whole lot quicker and extra exact,” stated the examine’s lead writer Jialong Shen, assistant analysis professor of textile engineering, chemistry and science at NC State. “You probably have entry to a printer, and the uncooked supplies, you may make this practical materials.”

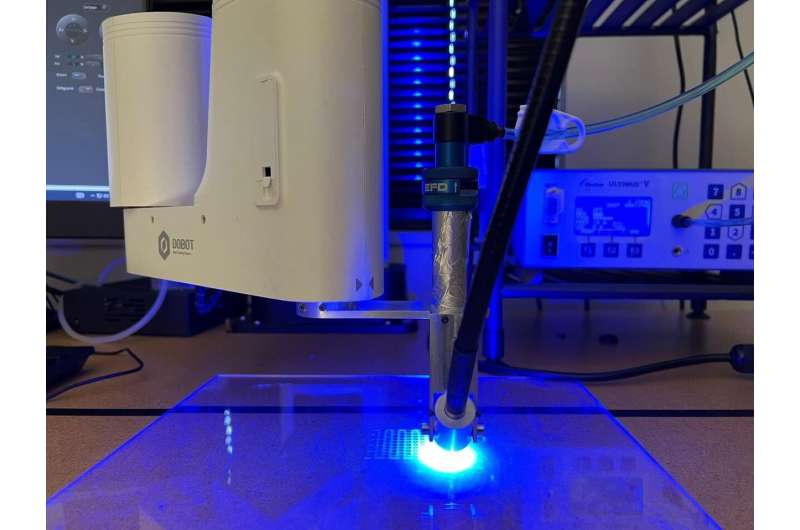

Within the examine, researchers within the NC State Wilson School of Textiles blended an answer containing two totally different natural compounds—or the printing “ink”—and an enzyme known as carbonic anhydrase. The researchers then printed thread-like filaments of the hydrogel right into a two-dimensional grid whereas solidifying the answer with UV gentle because it was printed.

“We formulated the hydrogel in a method that might be mechanically sturdy sufficient to be 3-D printed, and likewise extruded right into a steady filament,” Shen stated. “The inspiration behind our design was our personal cells, which have enzymes packed into compartmentalized areas, stuffed with a fluid. That form of atmosphere is sweet for serving to enzymes do their job.”

The researchers examined the properties of the fabric to grasp how effectively it might bend and twist, and investigated the filter’s carbon seize efficiency. In a small-scale experiment, they discovered the filter captured 24% of the carbon dioxide in a gasoline combination. Whereas the seize fee is decrease than what they’ve achieved in earlier designs, the filter was lower than an inch (2 centimeters) in diameter, and it might be made bigger and in several modular shapes as a way to stack them in a tall column. That might improve the seize effectivity, researchers stated.

“So as to get a better seize fee, we would wish to make the filter bigger in diameter, or stack extra filters on high of one another,” Shen stated. “We do not assume that is a difficulty; this was an preliminary take a look at at a small scale for ease of testing.”

The researchers additionally examined the filtration sturdiness of the fabric, and located it retained 52% of its preliminary carbon seize efficiency after greater than 1,000 hours.

“This work remains to be early stage, however our findings counsel there are new methods to make supplies for carbon seize gadgets,” stated the examine’s co-corresponding writer Sonja Salmon, affiliate professor of textile engineering, chemistry and science at NC State. “We’re providing hope for carbon seize.”

The examine, “Carbonic Anhydrase Enhanced UV-Crosslinked PEG-DA/PEO Extruded Hydrogel Versatile Filaments and Sturdy Grids for CO₂ Seize,” was revealed on-line in Gels. Co-authors included Sen Zhang and Xiaomeng Fang.

Extra info:

Carbonic Anhydrase Enhanced UV-Crosslinked PEG-DA/PEO Extruded Hydrogel Versatile Filaments and Sturdy Grids for CO₂ Seize, Gels (2023). DOI: 10.3390/gels9040341

Offered by

North Carolina State College

Quotation:

You may make carbon dioxide filters with a 3D printer (2023, Could 31)

retrieved 31 Could 2023

from https://phys.org/information/2023-05-carbon-dioxide-filters-3d-printer.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.